Understanding Paper Mill Machinery: The Backbone of the Pulp and Paper Industry

Release time:

2025-06-20

Paper mill machinery is a critical part of the pulp and paper industry, responsible for transforming raw materials like wood chips and recycled paper into finished paper products. The efficiency and effectiveness of paper mills depend heavily on the machinery used within them. Understanding the various types of equipment and their functions can provide valuable insights into the manufacturing processes that create the paper products we use every day.

At the heart of paper mill machinery is the pulping process, which breaks down wood fibers into a slurry. This can be achieved through mechanical, chemical, or semi-chemical methods. The choice of method affects the quality of the pulp produced. For instance, mechanical pulping typically retains more of the wood's natural properties but results in lower quality paper, while chemical pulping yields higher quality pulp suitable for a wider range of paper products.

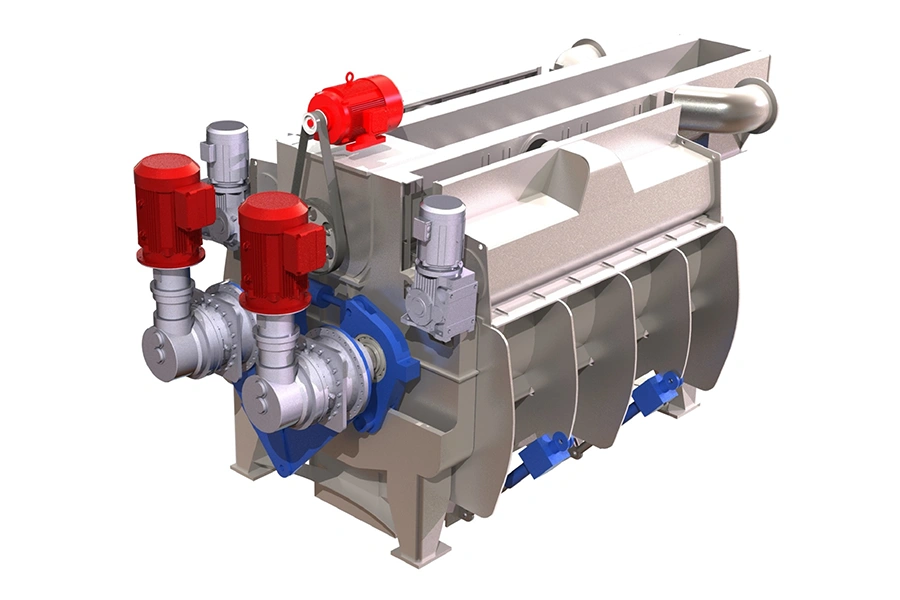

Once the pulp is prepared, it undergoes the papermaking process. The primary machine used in this phase is the paper machine, which consists of several key sections. The headbox evenly distributes the pulp onto a moving mesh screen, where water is drained, allowing the fibers to bond together. This is followed by the press section, where rollers squeeze out excess water and compact the sheet. Finally, the drying section uses heated cylinders to remove remaining moisture, resulting in a smooth, continuous sheet of paper.

In addition to the main paper machine, various auxiliary equipment is essential for optimizing efficiency and maintaining product quality. For example, a re-winder allows large rolls of paper to be cut into smaller, manageable sizes, while coating machines can apply various finishes to enhance paper properties, such as brightness or smoothness. Quality control systems are also integrated into the machinery to ensure that the final product meets specified standards.

Environmental considerations are increasingly shaping the design and operation of paper mill machinery. Modern machines are often designed to minimize energy consumption and waste generation. Many facilities now utilize closed-loop systems to recycle water and chemicals, contributing to sustainability in the industry.

In conclusion, paper mill machinery encompasses a range of sophisticated equipment integral to the production of paper products. Understanding its components and processes not only sheds light on the manufacturing of paper but also highlights the industry's commitment to efficiency and sustainability. As technology advances, the future of paper mill machinery looks promising, with innovations aimed at improving performance and reducing environmental impact. Whether you’re involved in the industry or simply curious, a deeper understanding of these machines reveals the complexity and care that goes into every sheet of paper we use.