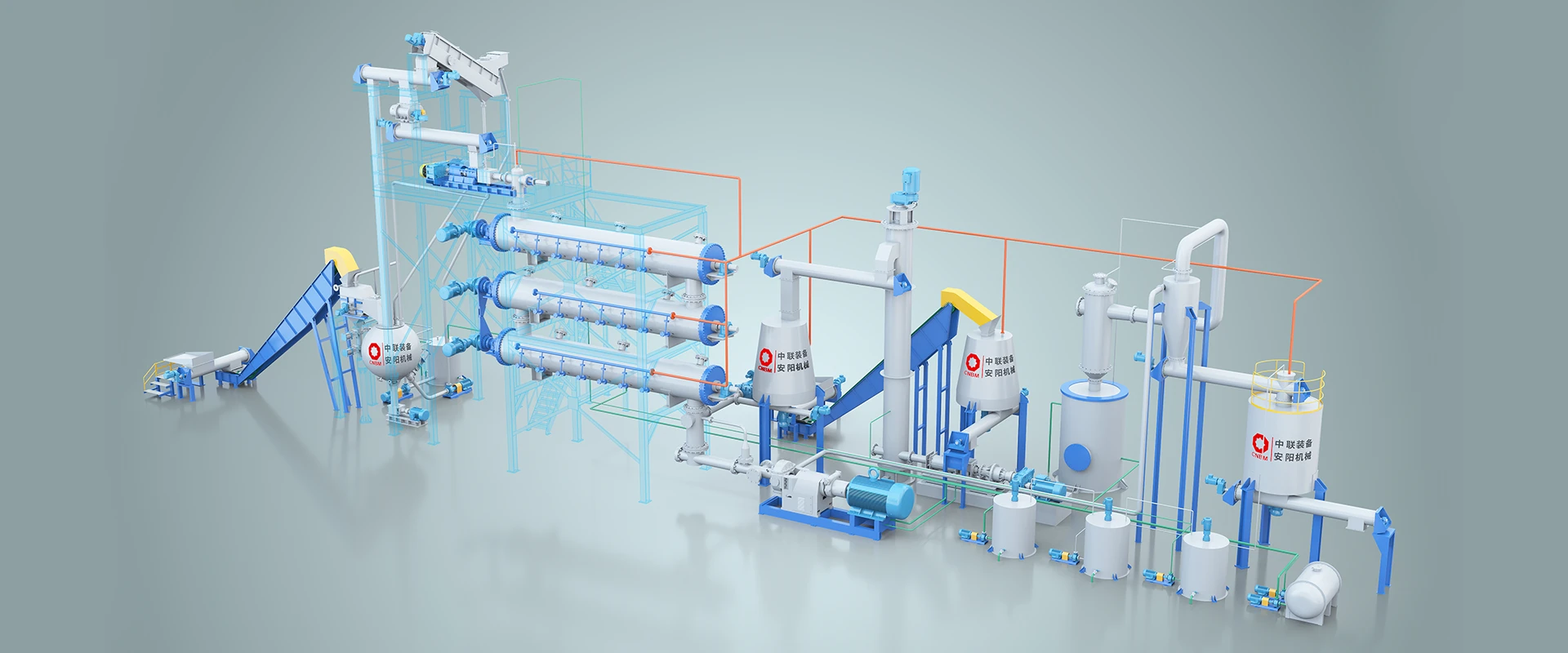

Pilot Line

Descriptions:

CNBM Anyang Machinery will rely on the Intelligent Mechanical Engineering Equipment Laboratory, adhering to an innovation-driven development strategy aimed at both domestic and international markets. We will continue to conduct research and development in various fields, including wet preparation, energy-saving intermittent replacement cooking, horizontal continuous cooking, vertical continuous cooking, pulp washing and bleaching, chemical thermomechanical pulp, semi-chemical mechanical pulp, mature supporting equipment for pulping production lines, and disc filters. Our goal is to promote the development of green, low-carbon, energy-efficient, safe, and intelligent pulping and papermaking production technologies and equipment, providing high-quality complete solutions and efficient, quality services to domestic and international users, and striving to become a leading enterprise in pulping and papermaking equipment in China.

Products: Chemical pulp, semi-chemical pulp, high-yield chemical mechanical pulp.

Processes: Suitable for alkaline, acid, and biological methods.

Raw Materials: Agricultural straw, forestry processing waste, wood, bamboo fiber, and other materials.

Production Method: Automated continuous production, equipped with instruments, electrical control, and DCS control systems.

Testing Purpose: To provide experimental data for clients in the early stages of projects and to support the development of process equipment.

Pilot Line is a high efficiency production solution designed to bridge the gap between laboratory innovation and full scale manufacturing. It offers companies a reliable environment to test, validate, and optimize new processes before they are transferred to mass production. The Pilot Line focuses on flexibility, precision, and scalability, allowing teams to accelerate development cycles and reduce risks.

🚀 Rapid Process Validation

The Pilot Line provides a controlled setting where new materials and technologies can be tested under realistic conditions. This allows engineers to evaluate performance, stability, and reproducibility without interrupting existing production lines. The system supports quick adjustments, enabling teams to refine parameters and shorten the time required to move from concept to commercialization.

🔧 Flexible Equipment Configuration

One of the key strengths of the Pilot Line is its modular design. Users can easily integrate different tools, adjust workflows, and expand capabilities according to project requirements. Whether the goal is to test a new coating technology, evaluate material behavior, or improve assembly methods, the Pilot Line offers the adaptability needed for continuous improvement. This flexibility also helps companies remain competitive in fast evolving markets.

📊 Accurate Data Collection

Reliable data is crucial during process development, and the Pilot Line provides high precision monitoring and reporting functions. It captures real time information regarding temperature, pressure, material flow, and other critical parameters. With detailed data insights, teams can identify potential issues early, optimize resource usage, and ensure consistent quality during scale up. This data driven approach supports better decision making and greatly reduces development risks.

🌱 Sustainable Production Practices

The Pilot Line is designed with sustainability in mind. It minimizes waste through optimized material usage and efficient energy consumption. The system also enables companies to evaluate environmentally friendly materials and energy saving techniques before integrating them into large scale operations. By supporting eco conscious development, the Pilot Line helps organizations achieve long term sustainability goals.

📦 Seamless Transition to Mass Production

A successful pilot stage reduces uncertainties when transitioning to full scale manufacturing. The Pilot Line provides all the tools necessary to verify process stability, product quality, and production efficiency. Once the process is validated, scaling up becomes smoother and more predictable. This lowers operational costs and ensures that final products meet market expectations.

For more information about our products, pricing, or to request a detailed quotation, please visit our official website at https://www.cnbmaym.com/contact_us.html.

Key words:

Pilot Line

Previous Page:

Next page:

Message

Related Products