隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

Vacuum Washer

Category:

Descriptions:

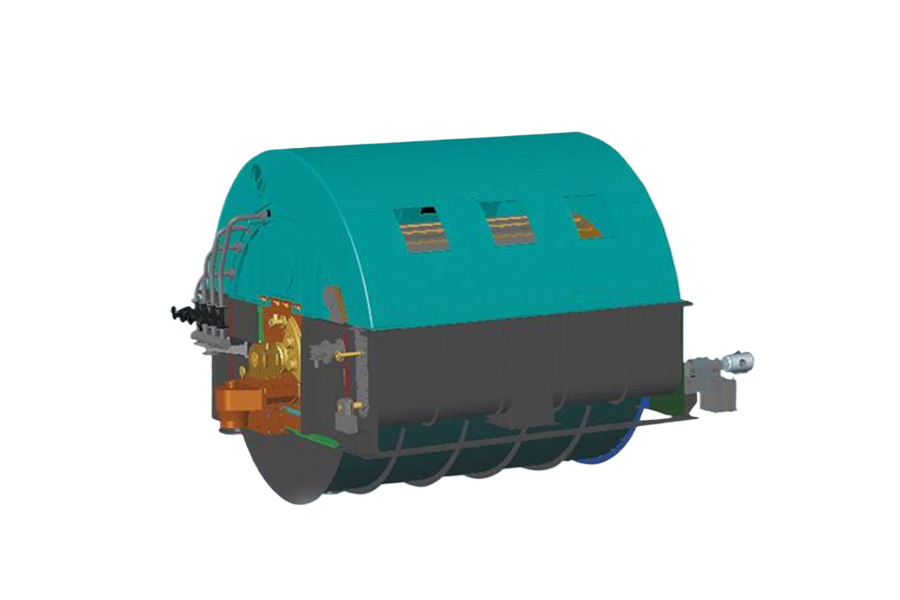

Vacuum Washer

CNBM Anyang Machinery Vacuum Washer, also known as the drum washer, is a widely used device for pulp washing. It is characterized by high washing efficiency, low dilution factor, and high concentration of black liquor extraction. It is commonly used in the washing and bleaching sections of pulp production lines.

The vacuum washer consists of several components, including the rotating drum, distribution valve, tank, pressing rollers, washing liquid spray system, discharge device, water leg, and vacuum system.

During operation, the rotation of the drum allows the pulp to pass through the natural filtration area, vacuum filtration area, vacuum washing area, and pulp discharge area, effectively washing the pulp.

CNBM Anyang Machinery Vacuum Washer Advantages

· High Yield: Achieves excellent yield per unit area.

· Enhanced Filtration Flow: The conical flow runner design of the drum body increases the filtrate flow rate.

· Stable Vacuum Control: The flat valve employs multi-point fixing technology, ensuring stable vacuum levels and high feeding concentration.

· Compact and Easy to Maintain: The flat distribution valve has a space-saving design, making maintenance straightforward.

· Increased Filtration Area: The corrugated plate design enhances the effective filtration area while preventing backflow and blockages.

· Improved Pulp Mixing: The dispersion-type material pressing and mixing technology boosts pulp mixing and washing efficiency, supported by innovative sealing techniques.

· Reliable Operation: Designed for stable operation with easy maintenance.

· Adjustable Transmission Speed: Enables reduced power consumption through adjustable speeds.

Vacuum Washer Technical parameters

|

Model/ |

Drum length( mm ) |

Drum Rotary Speed (rpm) |

Feed Concentration |

Discharge Concentration (%) |

Black Liquor Extraction (t/d) |

Bleaching Section(t/d) |

||||

|

straw |

Bamboo pulp |

Wood pulp |

straw |

Bamboo pulp |

Wood pulp |

|||||

|

ZNK35 |

3200 |

0.8~3 |

1.5~2.5 |

8~12 |

52~70 |

70~105 |

140~210 |

70~105 |

87~122 |

175~245 |

|

ZNK40 |

3650 |

0.8~3 |

1.5~2.5 |

8~12 |

60~80 |

80~120 |

160~240 |

80~120 |

100~140 |

200~280 |

|

ZNK45 |

4100 |

0.8~3 |

1.5~2.5 |

8~12 |

67~90 |

90~135 |

180~270 |

90~135 |

112~157 |

225~315 |

|

ZNK50 |

4550 |

0.8~3 |

1.5~2.5 |

8~12 |

75~100 |

100~150 |

200~300 |

100~150 |

125~175 |

250~350 |

|

ZNK55 |

5000 |

0.8~3 |

1.5~2.5 |

8~12 |

82~110 |

110~165 |

220~330 |

110~165 |

137~192 |

275~385 |

|

ZNK60 |

5450 |

0.8~3 |

1.5~2.5 |

8~12 |

90~120 |

120~180 |

240~360 |

120~180 |

150~210 |

300~420 |

|

ZNK65 |

5200 |

0.8~3 |

1.5~2.5 |

8~12 |

97~130 |

130~195 |

260~390 |

130~195 |

162~227 |

325~455 |

|

ZNK70 |

5600 |

0.8~3 |

1.5~2.5 |

8~12 |

105~140 |

140~210 |

280~420 |

140~210 |

175~245 |

350~490 |

|

ZNK75 |

6000 |

0.8~3 |

1.5~2.5 |

8~12 |

112~150 |

150~225 |

300~450 |

150~225 |

187~262 |

375~525 |

|

ZNK80 |

6400 |

0.8~3 |

1.5~2.5 |

8~12 |

120~160 |

160~180 |

320~480 |

160~240 |

200~280 |

400~560 |

|

ZNK85 |

6800 |

0.8~3 |

1.5~2.5 |

8~12 |

127~170 |

170~255 |

340~510 |

170~255 |

212~297 |

425~595 |

|

ZNK90 |

7200 |

0.8~3 |

1.5~2.5 |

8~12 |

135~180 |

180~270 |

360~540 |

180~270 |

225~315 |

450~630 |

|

ZNK95 |

7600 |

0.8~3 |

1.5~2.5 |

8~12 |

142~190 |

190~285 |

380~570 |

190~285 |

237~332 |

475~665 |

|

ZNK100 |

8000 |

0.8~3 |

1.5~2.5 |

8~12 |

150~200 |

200~300 |

400~600 |

200~300 |

250~350 |

500~700 |

|

ZNK105 |

7450 |

0.8~3 |

1.5~2.5 |

8~12 |

157~210 |

210~315 |

420~630 |

210~315 |

262~367 |

525~735 |

|

ZNK110 |

7800 |

0.8~3 |

1.5~2.5 |

8~12 |

165~220 |

220~330 |

440~660 |

220~330 |

275~385 |

550~770 |

|

ZNK115 |

8150 |

0.8~3 |

1.5~2.5 |

8~12 |

172~230 |

230~345 |

460~690 |

230~345 |

287~402 |

575~805 |

|

ZNK120 |

8500 |

0.8~3 |

1.5~2.5 |

8~12 |

180~240 |

240~360 |

480~720 |

240~360 |

300~420 |

600~840 |

Key words:

Vacuum Washer

Previous Page:

Next page:

Message

Related Products