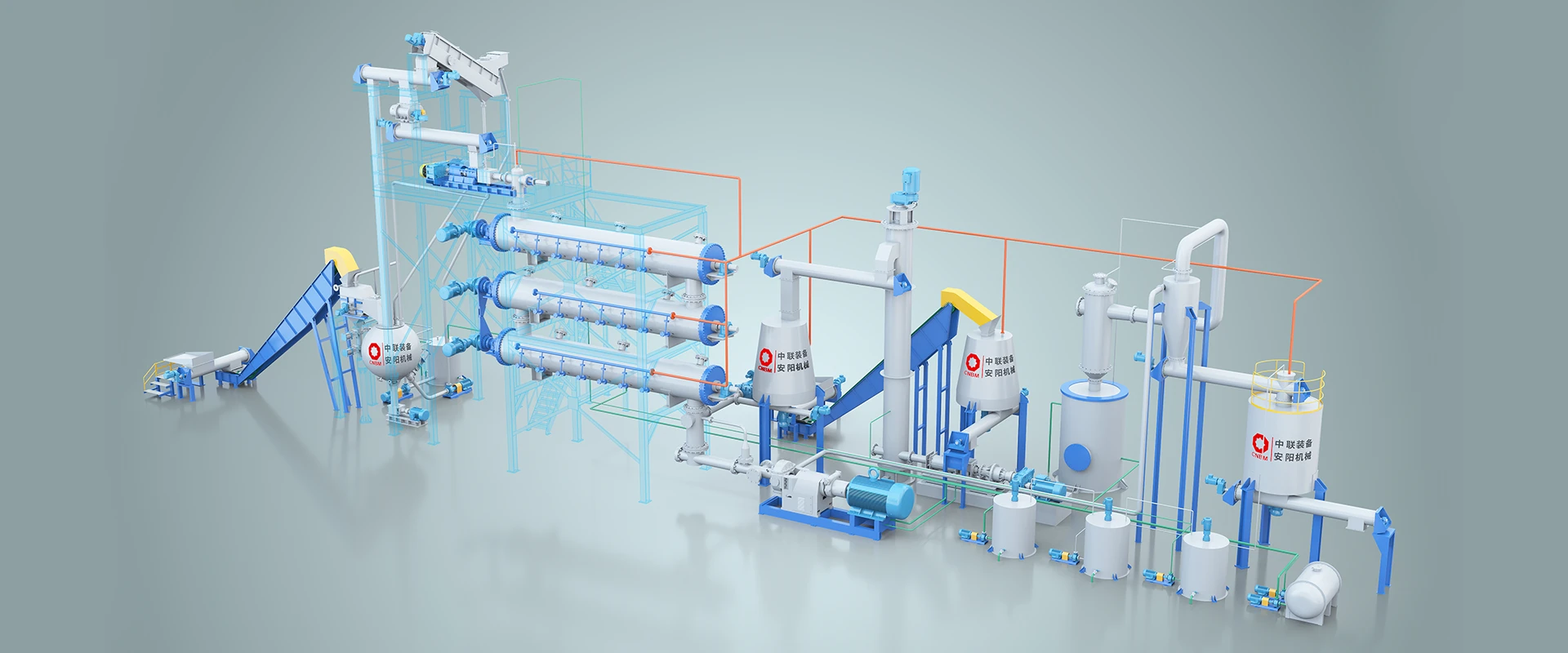

Bleaching Chemical Mechanical Pulping System

Descriptions:

CNBM Bleaching chemical mechanical pulping employs a combination of chemical pretreatment and mechanical refining. Initially, a mild chemical treatment (such as impregnation or cooking) is applied to remove a portion of hemicellulose and a small amount of lignin is either dissolved or remains largely intact, which softens the middle lamella. The softened chips are then processed in a refiner to separate the fibers into pulp.

The development of high-yield chemical mechanical pulping is significant for several reasons: it allows for the efficient and rational utilization of plant fiber resources, reduces pollutants in pulping wastewater, and meets product performance requirements.

Semi-chemical pulping builds on the principles of chemical mechanical pulping by using a stronger chemical treatment to partially break down lignin, followed by mechanical refining to separate fibers. This approach balances yield and quality, producing pulp with good strength properties while maintaining high fiber recovery. Semi-chemical pulping is widely used in the production of corrugated medium, packaging paper, and specialty papers where both strength and cost-efficiency are critical. By optimizing chemical dosage and refining intensity, manufacturers can achieve consistent pulp quality, reduce energy consumption, and minimize environmental impact, making semi-chemical pulping a sustainable choice for modern paper production.

Semi-chemical pulping combines partial chemical treatment and mechanical refining to produce high-yield, strong pulp efficiently. For more product details or related case studies, feel free to contact us.

Key words:

Bleaching Chemical Mechanical Pulping System

Previous Page:

Next page:

Message

Related Products