隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

隐藏域元素占位

Double-Roller Pulp Press

Category:

Descriptions:

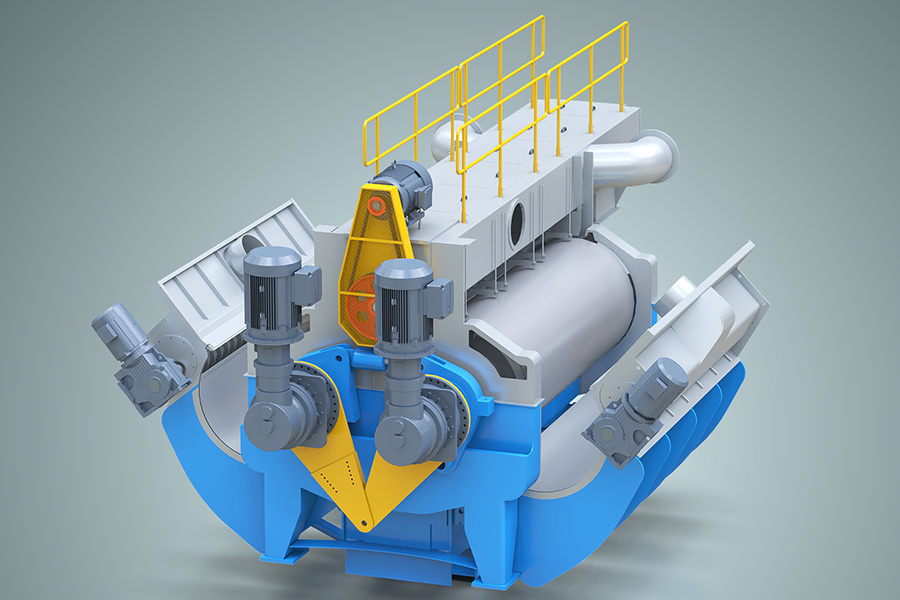

Twin Roll Press

CNBM Anyang Machinery Twin Roll Press is a high-pressure, high-concentration device designed for pulp washing, utilizing displacement and squeezing effects. It has gained widespread use due to its ability to extract black liquor at high concentrations and temperatures. For chemical pulps and mechanical pulps with lower freeness, shorter fibers, or higher consistency, the Twin Roll Press can effectively wash and concentrate the pulp at medium to low concentrations.

CNBM Anyang Machinery Twin Roll Press consists of several components, including a dewatering roller, a pulp tank, a pulp discharge system, and a sealing mechanism. During operation, the rotation of the dewatering roller causes the pulp to pass sequentially through the dewatering zone, displacement zone, and squeezing zone, achieving thorough washing and concentration of the pulp.

CNBM Anyang Machinery Twin Roll Press Advantage

Advanced Hydraulic System: Incorporates a globally recognized hydraulic drive system, which boosts stability and reliability.

Comprehensive Equipment: Features integrated washing, dehydration, and replacement systems for streamlined operation.

Improved Feeding Structure: Boasts a fully optimized pulp feeding design with independent intellectual property for enhanced proportioning.

Effective Sealing Mechanism: The updated sealing and scraping mechanism ensures efficient sealing during operation and is easy to manage.

Enhanced Filtration: Provides a larger filter area, improved replacement functionality, and superior pulp washing performance.

High Automation: Engineered for high automation, simplifying operation and enhancing efficiency.

Twin Roll Press Technical Parameters

|

Model/ |

Roll Length |

Roll Diameter |

Roll Speed (rpm) |

Inlet Concentration(%) |

Outlet Concen-tration |

Production Capacity |

||

|

Straw/ |

Bamboo Pulp |

Wood Pulp |

||||||

|

SJ712 |

1200 |

700 |

2~20 |

3.5~10 |

20~35 |

30~40 |

60~80 |

80`100 |

|

SJ915 |

1500 |

900 |

2~15 |

3.5~10 |

20~35 |

40~60 |

85~120 |

130~160 |

|

SJ920 |

2000 |

900 |

2~15 |

3.5~10 |

20~35 |

55~85 |

125~160 |

175~210 |

|

SJ928 |

2820 |

900 |

2~15 |

3.5~10 |

20~35 |

80~120 |

165~220 |

250~300 |

|

SJ935 |

3500 |

900 |

2~15 |

3.5~10 |

20~35 |

110~150 |

225~280 |

310~370 |

|

SJ940 |

4000 |

900 |

2~15 |

3.5~10 |

20~35 |

120~170 |

220~310 |

350~400 |

|

SJ945 |

4500 |

900 |

2~15 |

3.5~10 |

20~35 |

160~180 |

285~350 |

400~480 |

|

SJ1532 |

3200 |

1500 |

2~15 |

3.5~10 |

20~35 |

220~350 |

450·600 |

700~800 |

|

SJ1540 |

4000 |

1500 |

2~15 |

3.5~10 |

20~35 |

400~550 |

800~1000 |

1200~1500 |

|

SJ1550 |

5000 |

1500 |

2~15 |

3.5~10 |

20~35 |

500~650 |

1000~1300 |

1700~1800 |

|

SJ1572 |

7200 |

1500 |

2~15 |

3.5~10 |

20~35 |

750~1000 |

1500~1800 |

1500~3000 |

Key words:

Double-Roller Pulp Press

Previous Page:

Next page:

Message

Related Products