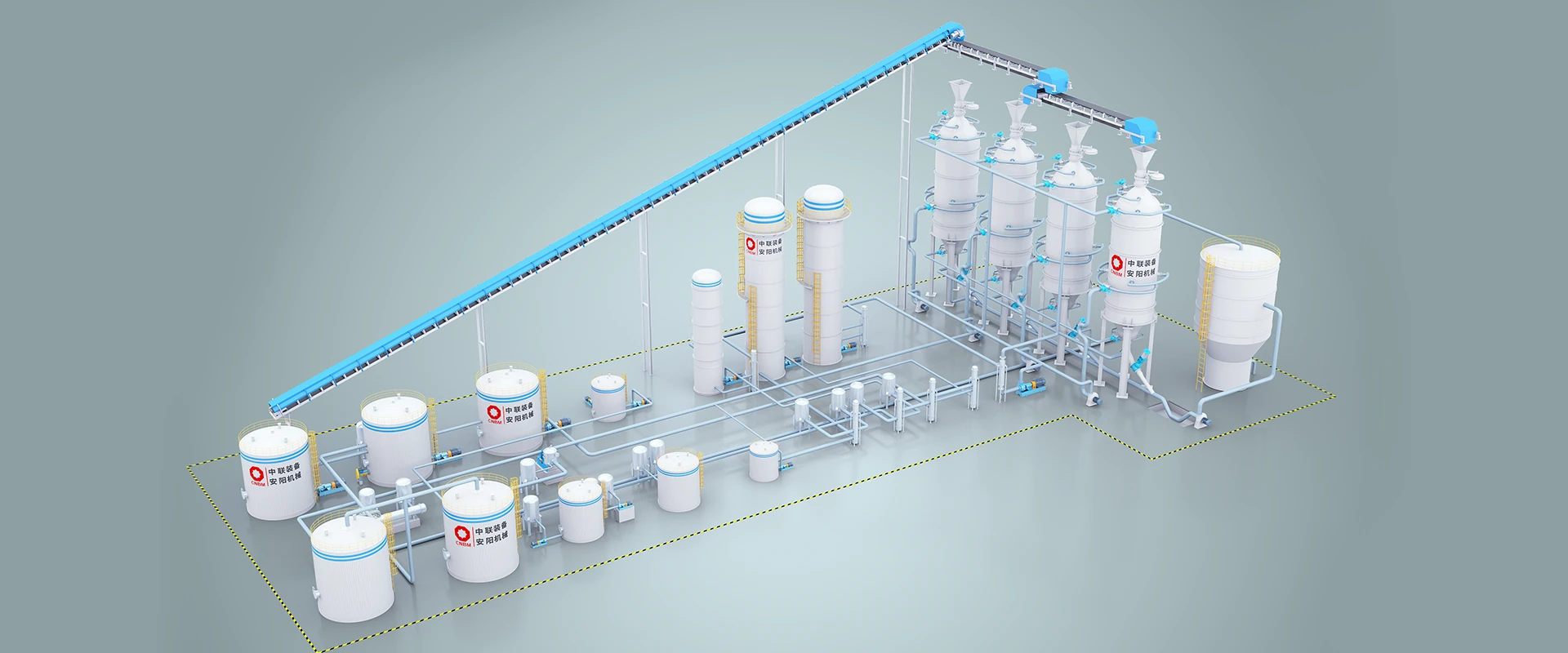

Chemical Recovery Plant

Descriptions:

The alkali recovery system is designed to reclaim chemicals and energy from the black liquor generated in the alkaline pulping process. Modern wood pulp recovery efficiency typically ranges from 95% to 98%, while straw pulp mills achieve recovery efficiencies of approximately 85% to 90%. This plays a crucial role in the sustainable development of the paper industry.

The main steps in the alkali recovery process include: concentrating black liquor in multi-effect evaporators to form strong black liquor; oxidizing and removing silica from the black liquor; further concentrating the black liquor to meet the requirements of the recovery boiler; incinerating the black liquor in the recovery boiler; dissolving the molten material from the recovery boiler to form green liquor; causticizing green liquor with lime to produce white liquor; and calcining white mud to recover lime.

The primary contributions of alkali recovery systems to the pulping industry are significant energy savings and reduced pollution.

Key words:

Chemical Recovery Plant

Previous Page:

Next page:

Message

Related Products