Production Lines

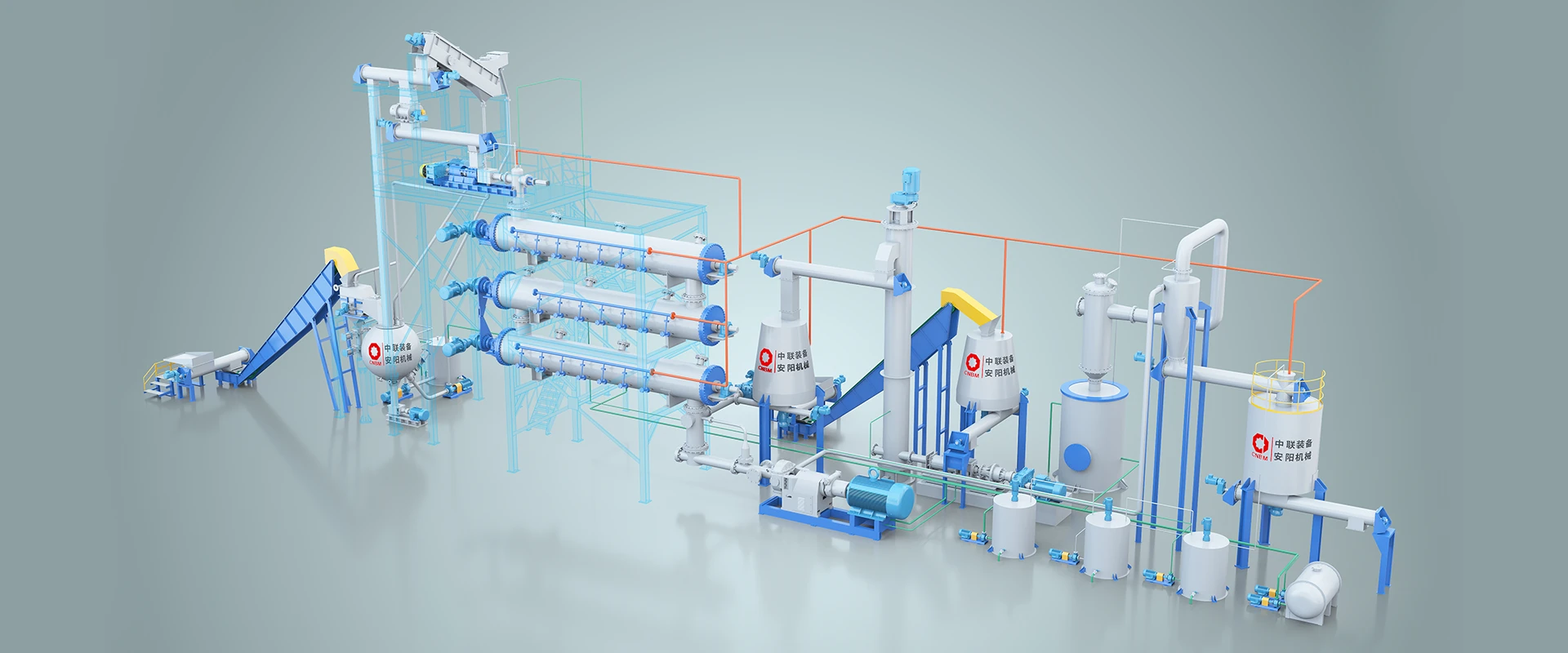

Bleaching Chemical Mechanical Pulping System

The development of high-yield chemical mechanical pulping is significant for several reasons: it allows for the efficient and rational utilization of plant fiber resources, reduces pollutants in pulping wastewater, and meets product performance requirements.

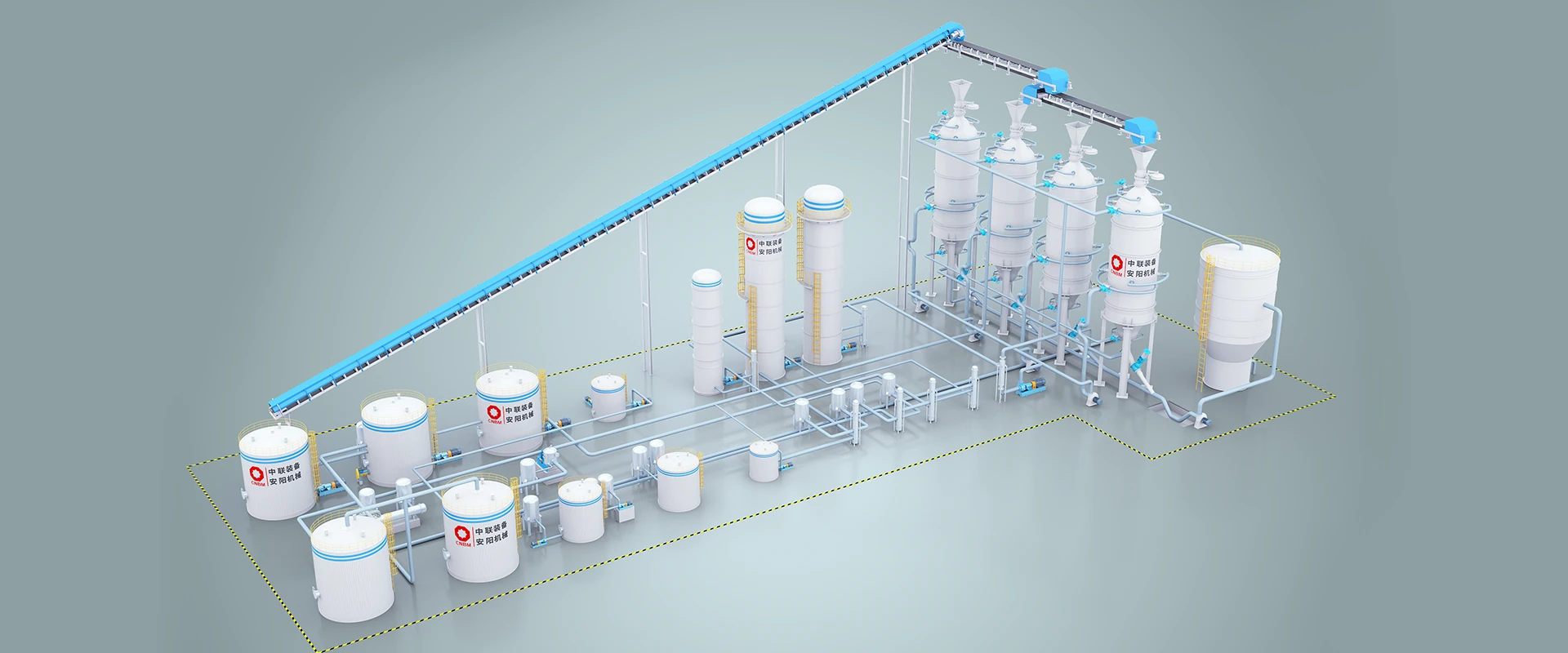

The alkali recovery system is designed to reclaim chemicals and energy from the black liquor generated in the alkaline pulping process. Modern wood pulp recovery efficiency typically ranges from 95% to 98%, while straw pulp mills achieve recovery efficiencies of approximately 85% to 90%. This plays a crucial role in the sustainable development of the paper industry.